07

10 2025

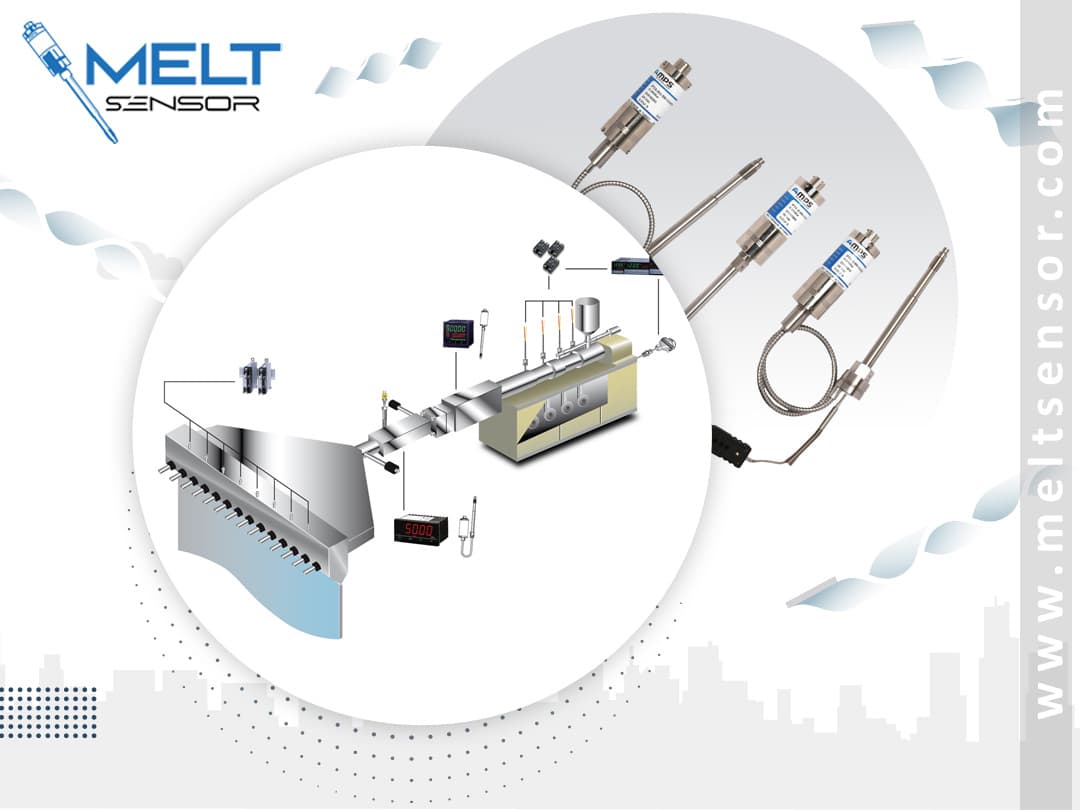

Stability in the Extrusion Process with Melt Pressure Sensors

In the plastics and polymer processing industry, the efficiency of extrusion lines is directly dependent on pressure control. Fluctuations in molten material pressure during production can negatively impact product quality and process stability. Therefore, melt pressure sensors play an essential role in modern extruders and gear pump systems.

Why Are Melt Pressure Sensors Important?

Melt pressure sensors continuously monitor the pressure of the molten polymer, providing instantaneous information to control systems. This allows for optimal adjustment of pumps, motors, and controllers within the line. Using the correct pressure sensors:

Product thickness and dimensions remain constant, and waste rates are reduced.

The load on the extruder's mechanical parts is reduced, extending its lifespan.

Energy consumption is more efficient.

Operators can detect potential blockages or imbalances in advance.

The Effects of Pressure Fluctuations

If the system lacks melt pressure sensors or the wrong type of sensor is selected, process control will be impaired. This causes thickness variations, surface irregularities, and dimensional deviations in products exiting the mold. Furthermore, pressure fluctuations can create undesirable mechanical stresses on gear pumps and molds. This increases maintenance costs and leads to production downtime.

Criteria for Choosing the Right Sensor

Manufacturers like MeltSensor offer a variety of pressure sensor solutions suitable for different industries. The following factors should be considered when selecting the right sensor:

Operating Temperature: Depending on the polymer type, sensors capable of operating above 300°C may be required.

Pressure Range: The selection should be appropriate for the maximum pressure in the line.

Material Compatibility: Sensors with PTFE, Inconel, or stainless steel diaphragms are resistant to various chemicals.

Output Signal: Outputs such as mV, V, or 4–20 mA should be compatible with the control system.

An incorrectly selected pressure sensor can fail quickly, leading to significant production losses.

Process Optimization and Energy Efficiency

Melt pressure sensors are important not only for safety but also for energy savings. Pump and extruder motors can provide constant flow with lower energy consumption compared to sensor data. This reduces both carbon footprint and operating costs.

Maintenance and Calibration

For optimal performance, melt pressure sensors should be regularly inspected and calibrated. Zero drift can occur in the sensors over time. To prevent this, periodic calibration is necessary, and the sensor tips should be kept clean. Furthermore, the integrity of cable connections directly affects signal quality.

Stability in extrusion processes depends on accurate measurement technologies. Melt pressure sensors are critical for achieving constant pressure and high-quality products in the production line. MeltSensor is a reliable partner in the industry, offering high-precision pressure sensor solutions tailored to various needs.